Description

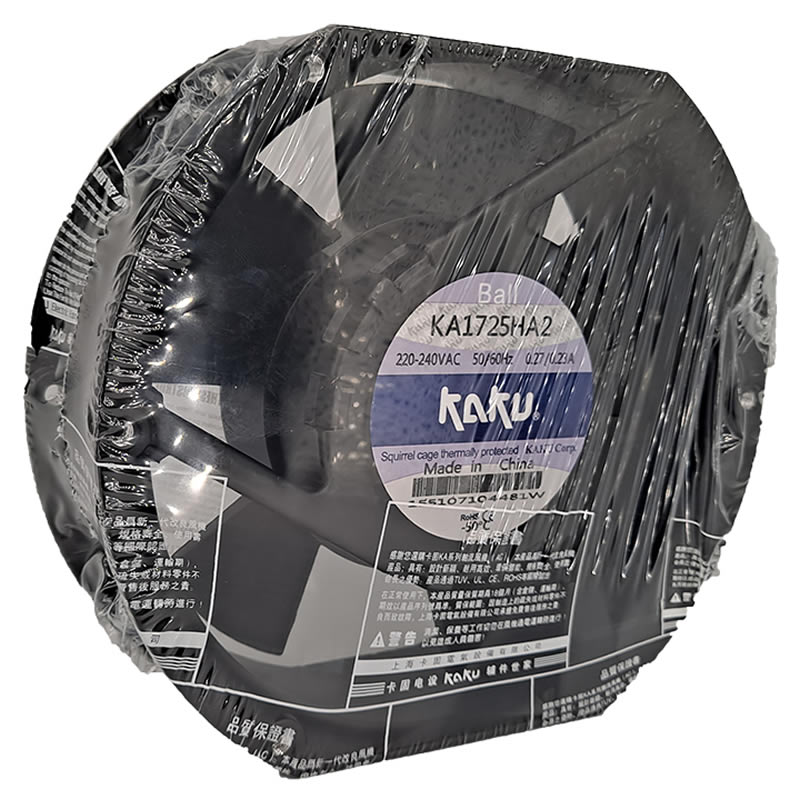

KA1725HA2 KAKU 170x150x51mm 220~240VAC 0.27A Ball Bearing 245CFM 3300RPM 59dB(A) 2Terminals AC axial fan

kAKU The insulation treatment of the coil winding of the axial fan has the following functions:

a. Increase mechanical strength

b. Improve insulation level

c. Prevent moisture intrusion

d. Increase thermal conductivity between windings

The traditional fan varnishing process: 3 seconds of varnishing at room temperature → 30 minutes of baking at 100℃, poor permeability and adsorption, only surface adsorption can be achieved. Since the fan generates heat when it is running, the undried paint evaporates, which has a corrosive effect on the fan. This is why the general fan can smell the paint.

The process of varnishing of the coil winding insulation of KAKU AC fan (KA1725HA2B) is as follows:

1) Stator preheating (110℃-130℃): remove moisture and impurities

2) Air cooling 80℃: easy to paint, too high temperature will deteriorate the paint, too low temperature will not penetrate

3) Dip in paint for 45 seconds. Paint (30℃-40℃)

4) Gel curing (baking): 120℃-150℃

Specifications

| Model | KA1725HA2 |

|---|---|

| Manufacturer | Delta Electronics |

| Dimensions | 170x150x51 mm |

| Voltage Rating | 220 ~ 240 VAC |

| Current Rating | 0.27 A |

| Bearing Type | Ball Bearing |

| Fan Type | AC |

| Air Flow | 245 CFM |

| Fan Speed | 3300 RPM |

| Noise Level | 59 dB(A) |

| Country of origin | China |

| Condition | New |

| Termination | 2 Terminals |

| Number of blades | 5 |

| Subcategory | AC axial fan |

Reviews

There are no reviews yet.